In industrial production, dust filter bags play a crucial role as they are related to environmental quality and production efficiency. However, when choosing dust filter bags, the choice between quality and price often puts enterprises in a dilemma.

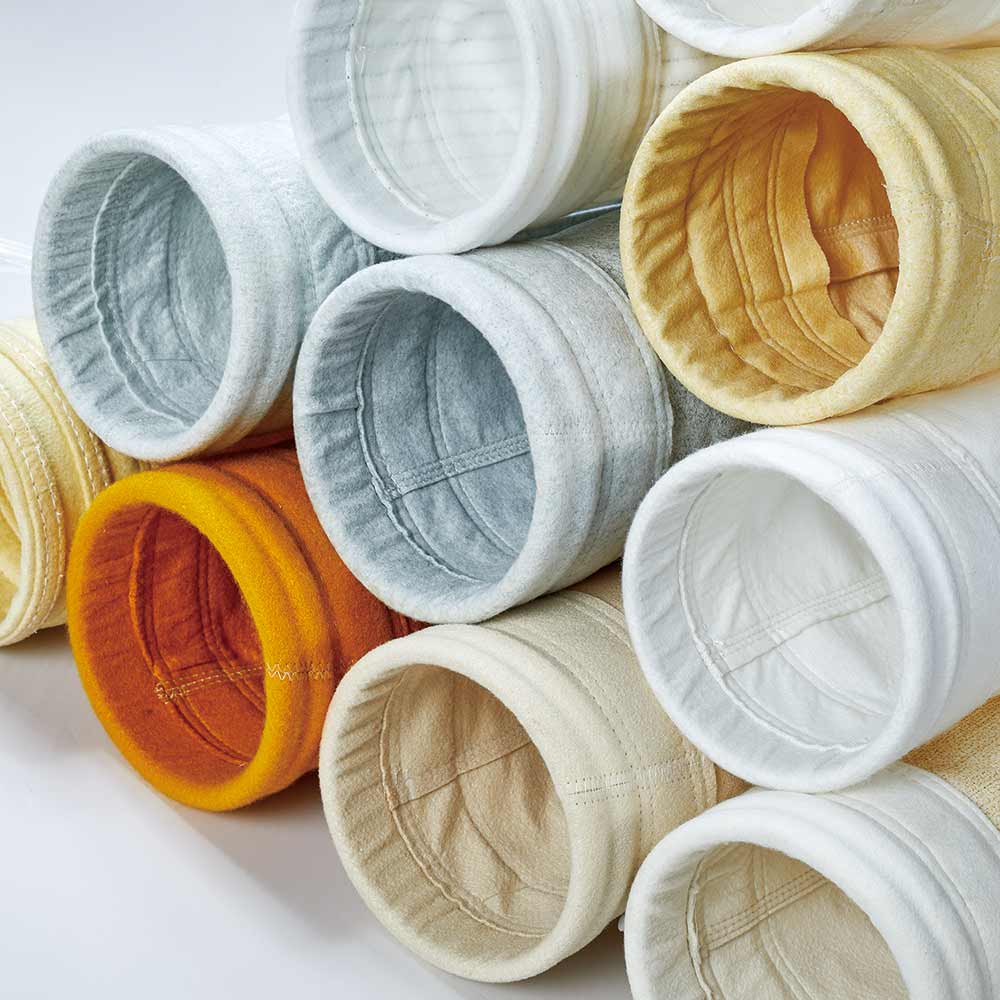

dust filter bags made of new materials have unique characteristics in terms of cost and performance. In terms of cost, the raw material cost is relatively high. For example, high-performance materials such as polytetrafluoroethylene have a high raw material price. At the same time, the research and development and production costs are also huge. A large amount of funds and time need to be invested in research and development. Special processes and equipment may also be used in the production process. This leads to a relatively high market price. But in terms of performance, filter bags made of new materials have obvious advantages. It has the ability of high-efficiency filtration, can meet stricter environmental protection requirements, and achieve higher filtration efficiency and lower emission concentration. It also performs well in durability, being wear-resistant, corrosion-resistant, and high-temperature resistant, greatly prolonging the service life of the filter bag. Moreover, new materials are highly adaptable and can adapt to harsh environments such as high temperature, high humidity, and corrosive gases.

In contrast, dust filter bags mixed with old materials have a lower cost. In terms of raw material cost, old materials are low in price. Through reasonable proportioning and reuse, the overall production cost can be reduced. The research and development cost is also saved because there is no need for a large amount of new material research and development work. The production process may use mature processes and equipment to improve efficiency and reduce costs, and the market price is more competitive. However, in terms of performance, filter bags mixed with old materials may be slightly inferior in filtration efficiency and durability, and their applicability is limited. They are more suitable for working conditions with not particularly high performance requirements. In extremely harsh working conditions, the performance may not meet the requirements.

The reasons for the low price of dust filter bags are multifaceted. In terms of material cost, ordinary chemical fiber materials and domestic materials have relatively low costs, making filter bags using these materials have an affordable price. In terms of production technology, standardized production and simplified processes can reduce costs and improve price competitiveness, but may affect the performance of filter bags. The market competition is fierce. Manufacturers adopt low-price strategies to compete for market share. At the same time, supply chain optimization can also reduce costs. When there is a large demand, manufacturers will adopt a small-profit and high-sales strategy. Promotion activities will also cause prices to drop in the short term. In addition, technological innovation and policy support may also reduce production costs and selling prices.

However, we must keep in mind that “you get what you pay for.” Although low-priced dust filter bags may meet the needs in some cases, in occasions where there are high requirements for filtration efficiency, durability, and service life, choosing high-quality filter bags made of new materials is undoubtedly a wiser choice. If you choose filter bags with poor performance just because of the low price, it may lead to frequent replacement of filter bags, increase maintenance costs, and even affect production efficiency and environmental quality.

When choosing industrial Dust filter bags, enterprises should comprehensively consider factors such as specific application scenarios, performance requirements, and budgets. For dust removal systems that require high performance and long service life, don’t be stingy in investing in filter bags made of new materials; for occasions with limited performance requirements and budgets, filter bags mixed with old materials can also be an option. In any case, a balance must be found between quality and price to ensure that the selected dust removal filter bag can not only meet production needs but also not impose excessive cost burdens on enterprises. Only in this way can enterprises achieve sustainable development while ensuring environmental quality and production efficiency.